The

The

Responsible

Wrap.

Mono-material sustainable polyethylene

shrink film solutions.

SUSTAINABLE PACKAGING SOLUTIONS

Packaging that’s part of the solution.

You put a lot of effort into making the most sustainable product possible. The packaging you use should be held to the same standard.

Blue Mountain Plastics (BMP) Extrusion is an advanced film extrusion and printing facility passionate about finding more sustainable packaging solutions. Through constant innovation, we are able to include 30% recycled content into our mono-material polyethylene film – without sacrificing durability and performance. In the future, we hope to get that number even higher.

There’s no limit to our innovation.

Since we own and operate our own film extrusion and printing facility, we’re able to test and develop new processes and technologies to help us achieve our goal of increasing recycled content and improving the recyclability of our LDPE (low density polyethylene) shrink film.

Less means so much more to us.

Our mission is to find new ways to use less materials while never sacrificing strength and durability. This has helped us use less plastic while creating less waste. That’s why our thin gauge, high-strength engineered film is not only perfect for heavy products – it also reduces the amount of plastic required by as much as 12.5%.

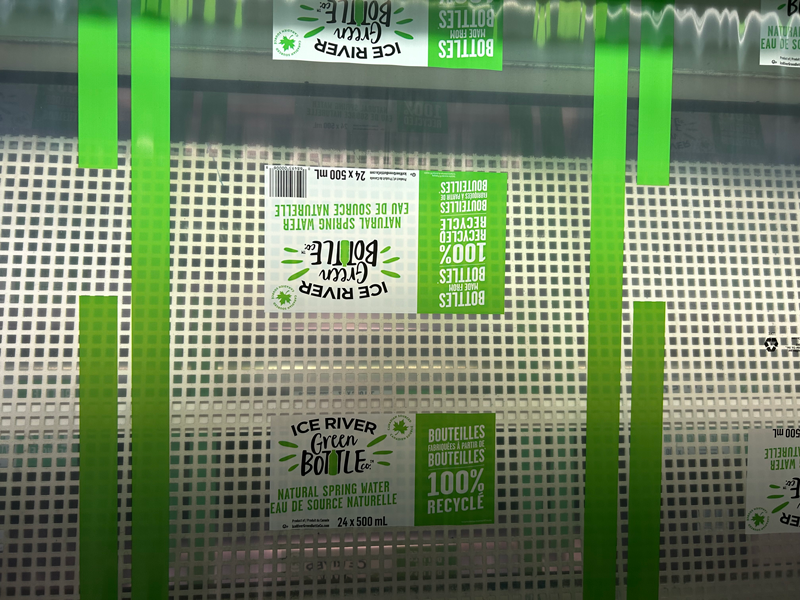

Beverage

Food

SUSTAINABILITY

Sustainability that’s nothing short of outstanding.

Our goal isn’t just to provide the highest quality polyethylene shrink film possible – it’s to push the entire industry to adopt more sustainable packaging practices

Our unwavering commitment to environmental stewardship pushes us to harness the latest advancements in sustainable materials and manufacturing processes in order to produce polyethylene shrink films that minimize ecological footprint without compromising performance.

It all starts with your recycling.

When you recycle, you not only help the planet – you help us be more environmentally responsible.

Post-Consumer Recycled Content (PCR) – along with Post-Industrial Recycled Content (PIR) – plays a vital role in our process. At the moment, we’re able to consistently maintain 30% recycled content and hopefully more in the near future.

Film you can feel confident in.

The state-of-the-art technology in our facility allows us to create high-end products with industry-leading efficiency – capable of packaging heavy products while using the least amount of plastic possible.

Quality you can always count on.

Every facet of production – from research and development to manufacturing, warehousing, and distribution – is all controlled under one roof. This holistic control ensures meticulous attention to detail and unwavering quality across each step of the process.

Our unique process epitomizes innovation, and customer satisfaction, making us a trusted leader in the sustainable shrink bundling film industry.

PRODUCTS

A greener future. One shrink wrap at a time.

What if you could prioritize environmental responsibility without compromising on performance?

Crafted with cutting-edge technology and eco-conscious materials, our shrink film not only delivers exceptional packaging quality and protection but also reduces carbon footprint. By choosing our product, you can not only demonstrate your commitment to sustainability – you can enjoy the benefits of efficient and reliable packaging solutions.

A one-of-a-kind approach to packaging.

At the heart of our operations lies a unique process for crafting sustainable Polyethylene shrink film that stands out in the industry. From inception to delivery, we prioritize sustainability, innovation and excellence.

BMP Extruder

Varex 5 layer line

- Ability to produce wide offerings of PE film

- Modular winding system

- Specs

- Width – Up to 2200mm

- Standard Gauges – 1.5miL – 15miL

- Standard Blends – 30% Recycled Content

- Surfaces – Treated – low slip to high slip, untreated

Printing Press

Flexographic Press – W & H Novoflex

- Highest print quality

- Printing speed up to 800 m/min

- Automated job changeovers

- Finishing – Perforated films available

- Specs

- 8 colour capability

- Printing up to 1650mm width

- Repeat length up to 1250mm

- In-house ink mixing

- High precision automated mounting

INDUSTRIES

Together, we’re leading the way to sustainability.

The shrink packaging industry is one that fosters collaboration and brand partnerships, encouraging stakeholders to work together towards a more sustainable future. Driven by a growing awareness of environmental issues and consumer demand for greener alternatives, we are pioneering innovative solutions that minimize carbon footprint, reduce waste, and promote circular economy principles.

Beverage

Food

Contact

Get in touch.

How can we help you? Do you have a question about our sustainable packaging solutions? Do you need a quote? Fill out the form below and we will get back to you shortly.

You can also give us a call at 1-844-764-7336 or send us an email to Info@bmpextrusion.ca.

Have a great rest of your day!